High importance on surface finish selection

An appropriate surface finish can improve the aesthetic appeal of extruded aluminum profiles, making them look more attractive aesthetically. A shiny and smooth surface finish will sparkle up the aluminum profiles, while a matte appearance is classy and modern. The choice of surface finish, if done correctly, can give a product a different look and feel that may be more attractive to customers.

Finishing has the ability to make a protective barrier against corrosion that will guarantee good quality of aluminum profiles for long-term usage. Aluminum is a robust and light material, but it can be corroded easily in harsh environmental conditions. Customized Aluminum Profile, surfaces that undergo a protective coat to protect them from corrosive forces and thus exponentially extending their life duration, can be used for a large variety of applications indoors and outdoors.

Kinds of pulleys

Anodized, all kinds of pulleys such as a hard anodize which provides aluminum with increased hardness followed by surface grinding or simply were grinding the splined main shaft and wheels and thus these types offered greater strength or more related to fragile fine features on surfaces Enable roughness. Making the surface of an aluminum profile textured will make it easier to grip, helping it withstand wear and tear, which is why it is commonly used in high-traffic areas and heavy-duty applications. The correct choice of surface finish can improve the functionality and help adapt a profile to different requirements so that it works optimally in specific conditions.

Surface finish as a conscious design process

It can be another way to build in or highlight your brand values over a competitor's. extruded aluminum profiles can be factory-finished with an almost unlimited variety of looks and textures to further cater a company's branding and styling, achieving a common design aesthetic throughout product lines. Manufacturers can use high-quality surface finishes to differentiate themselves from competitors on the market, highlighting their brand values and dedication to quality.

Surface finishes provide great versatility and customization possibilities

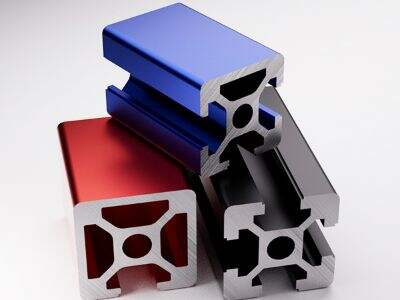

Enabling manufacturers to develop distinct designs and finishes that they are looking for. Anodized finishes in any color of the rainbow and powder-coated metallic finishes can be applied to your aluminum profiles and are only just a few ways to customize them. Facility designers, with the power to combine diverse surface finishes, are free to follow their imaginations and produce entirely novel and striking designs to differentiate their products in the market.

In summary, the choice of surface finish has an important to influence on the appearance and integrity of custom extruded aluminum profiles. Aluminum profile surface finish, both can be used to improve the appearance and functionality signifi¬cantly life and even the corporate identity supported, increased customization reinforcements. Common realizes the significance of surface finish and partners with its clients to deliver top-notch aluminum profiles that combines both quality, requirements, as well crim inspects of the customers. When you choose Common for your extruded aluminum profiles, you can trust that the products are the best in quality and with great surface finishes to provide a long polish life to your aluminum finished goods.