Understanding Aluminum Alloys and Performance Requirements

Overview of aluminum alloy series (1000-7000) and their industrial applications

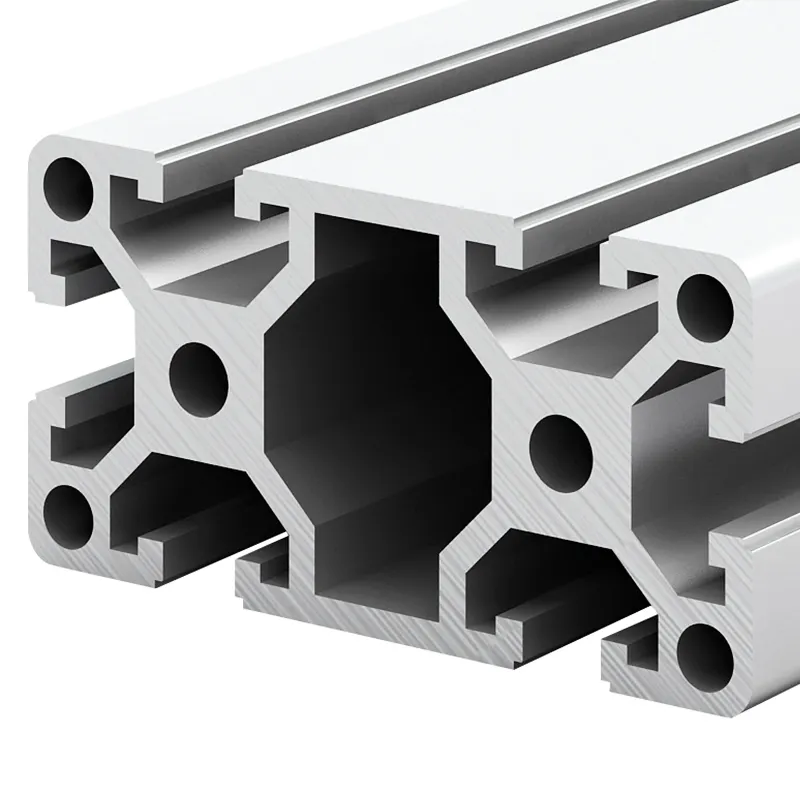

What makes aluminum so versatile? Well, it all comes down to those seven main alloy groups, each designed with particular properties in mind. Take the 1000 series for instance, which is basically 99% pure aluminum and works great for things like electrical wiring. Then there's the 6000 series that builders love because it strikes just the right balance between being strong enough and still easy to shape into different forms. Looking at some recent data from the Aluminum Alloy Stability Report released last year, we see that the 7000 series can handle pressures over around 450 MPa, which explains why these are so commonly used in aircraft parts. And if numbers matter to anyone reading this, a survey done among suppliers back in 2023 showed that about two thirds of all architectural extrusions worldwide come from the 6000 series alloys.

| Alloy Series | Primary Industry Use | Key Advantage |

|---|---|---|

| 5000 | Marine | Saltwater corrosion resistance |

| 6000 | Construction | High strength-to-weight ratio |

| 7000 | Aerospace | Ultimate tensile strength |

Key mechanical properties: strength, formability, and durability by alloy type

6061-T6 aluminum delivers a yield strength of 276 MPa with 12% elongation, enabling complex forming without fracture. In contrast, 2024-T3 prioritizes fatigue resistance (160 MPa cyclic load capacity), ideal for aircraft skins. Through precise tempering, extruders balance hardness (75-150 HB) and ductility to meet ASTM standards across diverse applications.

Corrosion resistance and environmental suitability for long-term performance

Marine-grade 5083-H116 loses just 0.02 mm/year in ASTM B117 salt spray tests—17 times more resistant than standard carbon steel. Anodized 6063 maintains integrity for 50 years under desert UV exposure, as confirmed by accelerated weathering simulations. For chemical environments, 3003-H14’s chromium coating reduces pitting corrosion by 89% compared to untreated surfaces.

Matching alloy selection to construction, automotive, and aerospace demands

Car manufacturers have been turning to 7000 series aluminum alloys for their crash management systems lately, which helps them cut down on weight compared to traditional steel options by around 40%. When it comes to high rise construction, architects often go with 6061-T6 because of its impressive shear strength of about 240 MPa for those curtain wall mullions. Meanwhile, companies making parts for airplanes tend to ask for 7075-T651 alloy when they need wing ribs that can handle roughly 14 kN per square meter of load pressure. With cities growing faster than ever before, choosing the right metal mixtures might actually help slash building material waste by approximately 22% each year. Some studies from Vista Architectural back up this claim too, though specifics remain somewhat vague in public reports.

Quality Assurance Processes in Aluminum Profile Manufacturing

Raw Material Inspection and Aluminum Billet Quality Control

Quality begins with verifying billet composition using spectrometry to distinguish grades like 6061 and 6063. Even minor deviations in silicon or magnesium can reduce strength by up to 15% (Aluminum Association, 2023). Reputable manufacturers cross-check material certifications against international purity benchmarks, ensuring full traceability from ore to finished profile.

In-Line Dimensional Accuracy and Tolerance Monitoring During Extrusion

Real-time sensors monitor ram pressure (±50 bar) and temperature (450-500°C) to maintain extrusion consistency. Laser measurement systems ensure tolerances within ±0.1 mm—critical for precision sectors like aerospace. Advanced producers employ predictive algorithms to adjust dies dynamically, reducing dimensional defects by 40% compared to manual methods.

Post-Production Testing: Salt Spray, Tensile Strength, and Batch Consistency

| Test Type | Standard | Performance Benchmark |

|---|---|---|

| Salt Spray Resistance | ASTM B117 | 1,500-2,000 hours (marine) |

| Tensile Strength | ISO 6892-1 | 290-350 MPa (6063-T6 alloy) |

| Batch Consistency | EN 755-9 | ±3% variation across batches |

Third-party labs validate these metrics, with top-tier suppliers maintaining 98% compliance across 15+ mechanical properties.

ISO Certifications vs. Real-World Quality Outcomes: What Truly Matters

While ISO 9001 is a baseline, 78% of manufacturers value real-world testing over certification alone (ASQ, 2023). Some ISO-certified suppliers still show high defect rates in UV or corrosion tests. Leading extruders combine certification with Statistical Process Control (SPC), conducting hourly audits to keep defect rates below 0.5%.

Surface Finishes and Treatment Options for Enhanced Performance

Anodizing vs. Powder Coating: Differences in Protection and Aesthetics

When metal gets anodized, it creates this special oxide layer that bonds right into the surface, usually between 3 to 25 microns thick. This process gives the material much better protection against rust and maintains that nice natural metal look people often want. Powder coating works differently by applying a kind of polymer that gets hardened with heat. One big advantage here is the wide range of colors available plus better protection from scratches. For those working near the coast where salt air is a real problem, tests show anodized surfaces can last about 1.8 times longer before showing signs of corrosion according to ASTM B117 standards. And when it comes to keeping their color, powder coatings hold up pretty well too, maintaining around 95% of their original vibrancy even after sitting out in sunlight for 5,000 hours straight.

Functional Benefits of Surface Treatments in Harsh or Visible Environments

| Treatment | Chemical Resistance | Temperature Tolerance | Aesthetic Versatility |

|---|---|---|---|

| Anodizing | High (pH 3-9) | ≤200°F | Limited metallic tones |

| Powder Coating | Moderate (pH 5-8) | ≤400°F | Unlimited RAL colors |

Recent studies show functional surface enhancements improve part longevity by 60-80% in industrial settings through combined corrosion and wear protection. This makes powder coating ideal for architectural components requiring both visual appeal and weather resistance.

Durability, UV Resistance, and Maintenance Requirements of Finished Profiles

Anodized profiles require only annual cleaning with mild detergents and perform reliably for 20+ years outdoors. Powder-coated surfaces offer excellent UV stability (ΔE <2 after ten years) but may need recoating every 12-15 years in high-traffic areas. In automotive trim applications, anodizing reduces maintenance costs by 37% compared to painted alternatives (SAE 2023 benchmarks).

Always verify treatment certifications align with your project’s ISO 12944 or AAMA 2605 compliance requirements when working with an Aluminum Profile Supplier.

Evaluating Supplier Credibility and Technical Capabilities

Assessing Manufacturer Reputation and Experience in Global B2B Markets

Start by evaluating a supplier’s operational history and client portfolio. Top-tier producers typically have 10+ years of specialized experience and verifiable projects in construction, automotive, or aerospace. Cross-reference ISO 9001 certification with customer testimonials—industry reports indicate 78% of procurement teams favor suppliers with transparent case studies over generic claims.

Transparency in Production Processes and Traceability of Materials

Reputable suppliers provide mill test certificates and full documentation of raw material origins. Third-party audits of extrusion and annealing processes mitigate quality risks, especially since 34% of structural failures stem from undocumented material substitutions (ASM International, 2023).

Engineering Support, Customization, and CAD/CAM Integration Services

Assess whether technical teams can convert designs into manufacturable profiles. Leading partners use DFM (Design for Manufacturing) analysis, cutting prototyping cycles by up to 60%. Suppliers with CAD/CAE integration achieve 2.3± faster project ramp-ups than those relying on legacy workflows, according to recent benchmarking studies.

Tooling Development Speed and Prototyping Efficiency for Custom Profiles

Evaluate die design capabilities and rapid prototyping systems. Advanced suppliers use AI-driven simulation to achieve ±0.1mm tolerances in first-article samples, accelerating time-to-market. For complex architectural systems, leading providers deliver functional prototypes within 14 working days—47% faster than industry averages.

When selecting an Aluminum Profile Supplier, prioritize partners who integrate ISO-certified quality systems with hands-on engineering expertise to ensure technical precision and supply chain resilience.

Cost-Effectiveness and Long-Term Value in Aluminum Sourcing

Balancing Upfront Cost With Lifecycle Value of High-Performance Profiles

Choosing profiles based solely on initial price risks long-term performance. Premium alloys can last 30-50% longer than standard options (Ponemon, 2023), with lifecycle savings outweighing higher upfront costs. For structural uses, 6061-T6 aluminum’s fatigue resistance and 25-year corrosion warranty justify its 18-22% price premium over entry-level alternatives.

Strategic Material Selection to Optimize Performance and Reduce Waste

Precise alloy matching reduces material waste by 12-18% in large-scale builds. One manufacturer achieved a 15% weight reduction in rail transit components using 6005A-T5 profiles—without sacrificing load capacity—thanks to tight extrusion tolerances (±0.1mm). This approach cut shipping costs by 9% and machining scrap by 21% versus conventional designs.

Case Study: Enabling Innovation in Rail Transit Through Reliable Aluminum Profile Supplier Partnerships

A Scandinavian metro network transitioned to 7xxx-series aluminum profiles for carriage bodies, cutting maintenance costs by 40% over eight years. The supplier’s alloy customization extended component replacement intervals from 5 to 9 years, proving how technical collaboration turns material investment into long-term operational advantage.

FAQs on Aluminum Alloys and Supplier Selection

What are the main types of aluminum alloys used in industries?

The main types of aluminum alloys include series 1000 to 7000, each with specific properties tailored for industries like construction, aerospace, and marine.

Why is it essential to select the right aluminum alloy for each project?

Choosing the appropriate alloy ensures optimal performance, minimizing weight without compromising strength, and improving corrosion resistance for long-term sustainability.

How do surface treatments like anodizing or powder coating enhance aluminum profiles?

Surface treatments provide extra protection against corrosion and wear, with anodizing offering natural metal aesthetics and powder coating delivering diverse color options and scratch resistance.

What factors should you consider when choosing an aluminum supplier?

Consider the supplier's reputation, experience, production transparency, and their capabilities in engineering support, customization, and compliance with quality standards like ISO.

Table of Contents

-

Understanding Aluminum Alloys and Performance Requirements

- Overview of aluminum alloy series (1000-7000) and their industrial applications

- Key mechanical properties: strength, formability, and durability by alloy type

- Corrosion resistance and environmental suitability for long-term performance

- Matching alloy selection to construction, automotive, and aerospace demands

- Quality Assurance Processes in Aluminum Profile Manufacturing

- Surface Finishes and Treatment Options for Enhanced Performance

- Evaluating Supplier Credibility and Technical Capabilities

- Cost-Effectiveness and Long-Term Value in Aluminum Sourcing

- FAQs on Aluminum Alloys and Supplier Selection