Modular Frameworks for Automation Systems Using Aluminum Profiles

The Role of T-Slot Aluminum Extrusions in Automation Frames

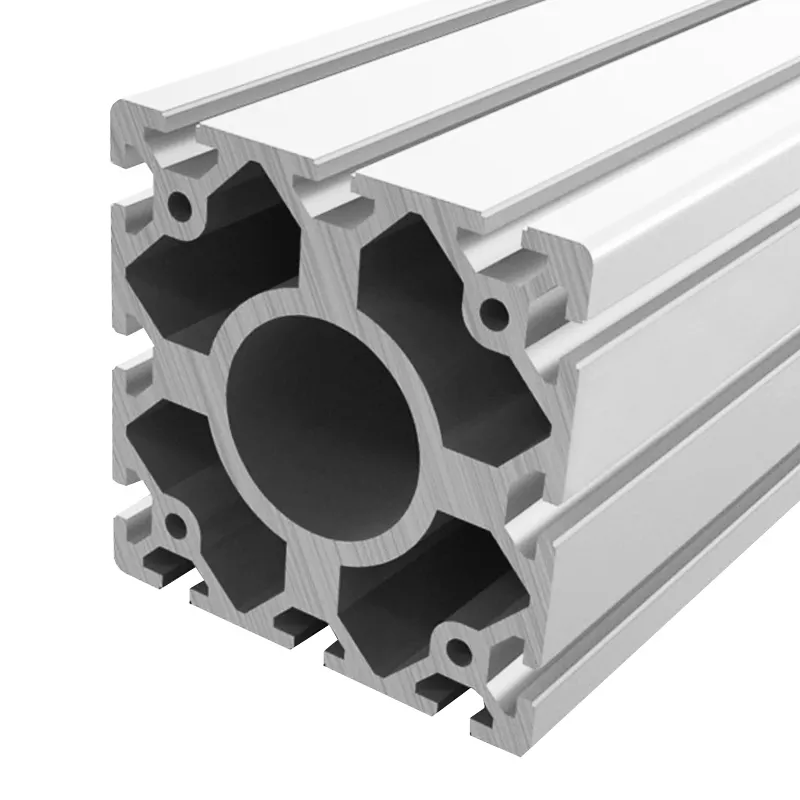

T slot aluminum profiles have become pretty much essential in today's automated systems. They weigh about 40 percent less than steel but still hold up just as well structurally, something the Automation Engineering Report noted back in 2023. What makes these profiles so useful is their special groove system that lets engineers snap together robotic workstations, conveyor belts, and those linear guides we see everywhere in factories. No need for all that welding anymore since everything just bolts right in place. And let's face it, this modular approach cuts down on setup time dramatically. Some companies report getting installations done in half the time it would take with old fashioned welded steel frames, which explains why so many manufacturers are switching over now.

Modular Design for Robotic Cells Using Aluminum Profiles

Aluminum profiles have become a go-to solution for manufacturers building those flexible robotic workcells that can keep up when product designs change on short notice. According to research published in Automotive Manufacturing Solutions back in 2022, plants that switched to these aluminum modular systems saw their downtime drop by nearly four fifths during those tricky model year switches. What really makes this work is the T-slot configuration. Operators can move around all sorts of components - from sensors to safety guards and tool mounting points - and get everything back online within just over two and a half hours. This kind of speed matters a lot in facilities where they're constantly switching between different product lines and need maximum flexibility without wasting precious production time.

Reconfigurable Automation Setups with Lightweight Framing

Lightweight aluminum assemblies support on-demand layout modifications for automated systems exceeding 1 ton. Production floors using modular aluminum frameworks report significant operational savings:

| Metric | Aluminum Systems | Traditional Systems |

|---|---|---|

| Reconfiguration labor cost | $320 | $1,150 |

| Energy consumption/ft² | 18 kWh | 29 kWh |

These metrics underscore aluminumâs role in enabling sustainable, adaptable manufacturing practices.

Case Study: Deploying Aluminum-Based Cells in Automotive Assembly Lines

A European electric vehicle manufacturer implemented aluminum profile-based automation cells for battery module assembly. The switch reduced cell construction costs by 53% while achieving vibration tolerances below 0.12 mmâmeeting stringent quality standards for high-voltage component manufacturing.

Trend: Shift Toward Flexible Manufacturing Systems Using Aluminum Extrusions

Global demand for aluminum extrusion-based automation components grew 19% year-over-year in 2023, driven by automotive and electronics manufacturers seeking scalable production solutions. Unlike rigid welded systems, aluminum frameworks allow factories to incrementally expand capacity through modular additions rather than wholesale equipment replacements.

Robotic and AMR Structures Built with Aluminum Profiles

Robot Mounting Frameworks Built with T-Slot Aluminum Profiles

T slot aluminum profiles are now pretty much the go to choice for robotic mounting systems because they offer both modularity and good load bearing capabilities. The extruded framework lets engineers put together, tweak, or grow robotic work cells without needing any welding at all. This is really important since around two thirds of automation projects need changes halfway through according to the 2023 report on materials used in automation. What makes these profiles stand out is their open channel design which lets sensors, pneumatic lines, and control wiring get integrated right into the structure. Assembly times drop about 40 percent when compared with old school steel frames, saving both time and money on installation costs.

Structural Integration in Autonomous Mobile Robots (AMRs)

The strength to weight ratio of aluminum is much better than steel when we compare their densities (about 0.097 lb per cubic inch compared to around 0.282 for steel). This makes aluminum really good choice for building AMR chassis and those tall sensor masts. Most manufacturers go with custom made aluminum extrusions because they can create all sorts of different shapes. These structures end up holding everything from batteries to lidar sensors and navigation hardware. The whole point is to keep the robot's overall weight below 150 pounds. Why does this matter so much? Well, lighter robots can run for longer periods between charges. We're talking about getting at least eight hours of operation time in most warehouse environments which is absolutely critical for day to day operations.

Use of Aluminum Profiles in Pick-and-Place Machines and Robotic Arms

Aluminum profiles machined using CNC technology offer the kind of dimensional stability needed for those fast moving delta robots and SCARA arms, typically holding within ±0.1mm tolerances. When it comes to packaging lines, end effectors made from aluminum extrusions can handle well over 200 cycles each minute, which is pretty impressive considering they have about 32 percent less inertia compared to their steel counterparts. What makes aluminum really stand out though is its natural ability to dampen vibrations, something that significantly boosts placement accuracy down at the micron level where things like semiconductor handling require absolute precision.

Controversy Analysis: Aluminum vs. Steel in High-Payload Robotic Structures

| Factor | Aluminum Profiles | Steel Framing |

|---|---|---|

| Max Payload Capacity | 2,200 lbs (static load) | 5,500 lbs |

| Corrosion Resistance | Superior (no coating) | Requires galvanizing |

| Reconfiguration Time | 15-30 minutes | 2-4 hours (welding) |

| Total Cost (10-yr) | $18,000 | $24,000 |

While steel remains dominant in gantry systems exceeding 5 tons, aluminum profiles dominate 78% of the sub-3-ton collaborative robot market due to reconfigurability and OSHA-compliant ergonomics. Recent fatigue tests show 6063-T6 aluminum withstands 10^7 stress cycles at 40 MPaâsufficient for most assembly and material handling tasks.

Conveyor and Material Handling Systems with Aluminum Extrusions

Aluminum Framing in Conveyor Systems and Industrial Equipment

According to the Material Handling Institute report from 2023, around 72 percent of all logistics conveyor systems today incorporate aluminum profiles because they offer such great modularity. The T-slot design makes putting together frames much faster, and these aluminum frames can actually hold up to 900 kilograms per meter despite being significantly lighter than steel counterparts. We're talking about roughly half the weight when compared to traditional steel options. From pharmaceutical manufacturing floors to car assembly lines, companies across various sectors depend on these extruded aluminum parts since they come in widths ranging between 300 and 2,400 millimeters. Plus, they fit right in with existing components like rollers, motors, and those sorting gates that help manage product flow. Recent studies conducted in 2023 showed something pretty impressive too: factories that switched to aluminum based conveyor systems saw their setup times drop by nearly three quarters whenever they needed to change production lines.

Guide Rail Mounting Structures with Linear Motion Compatibility

Aluminum guide rails that are precision aligned can reach positional accuracy around ±0.1 mm, which makes them ideal for moving delicate parts such as semiconductor wafers without damage. When manufacturers pair these rails with V-slot profiles and linear bearings, they end up with sliding systems that require almost no maintenance and can run pretty fast too—some models hit speeds of about 5 meters per second. What really stands out is the T-slot design. Operators can tweak the rail's parallelism on site without tearing apart whole sections of machinery. This feature matters a lot in bottling operations where lines process close to 1,200 containers every single minute. Being able to make quick adjustments saves time and keeps production running smoothly when things get hectic.

Sensor Mounting Brackets and Integration Points on Conveyor Frames

The latest aluminum conveyor frames come equipped with standard M6 and M8 threaded slots spaced at 40 mm intervals, which makes it possible to install photoelectric sensors and RFID readers without any tools. The convenience factor is pretty impressive actually. According to Automation World from last year, companies have seen their sensor setup expenses drop by around 34% in packaging plants alone. For those concerned about workplace safety, these systems often include specially designed side channels where emergency stop buttons and laser scanners can be placed. This helps meet those important ISO 13849 requirements for machine safety, something that plant managers take very seriously when assessing risk.

Machine Guarding, Workstations, and Safety Compliance with Aluminum Framing

Aluminum profiles have become indispensable for creating safe, adaptable industrial environments. Their combination of strength, corrosion resistance, and modularity enables manufacturers to meet strict safety regulations while maintaining operational flexibility. Below, we explore two critical applications where aluminum framing enhances workplace safety and efficiency.

Aluminum Profiles in Machine Guard Fabrication for Safety Compliance

T slot aluminum extrusions make it much easier to build machine guards that meet OSHA standards and keep workers safe from those dangerous moving parts and flying debris. One big plus is the smooth edges on these materials which means no sharp corners sticking out that could cut someone. Plus, the modular nature of T slot systems lets factories quickly change guard configurations when they upgrade their equipment. Manufacturing plants that need strict safety compliance find aluminum frames particularly useful because they work so well with clear polycarbonate panels and secure locking doors. What really stands out though is how straightforward maintenance becomes with pre drilled holes and standard connectors throughout the system. Technicians can take apart sections for inspection or repairs without needing special tools, which cuts down on downtime significantly compared to older methods.

Ergonomic Workstations Using Customizable Aluminum Assemblies

The light yet sturdy nature of aluminum makes it possible to create workstations that adjust to different heights according to what operators need throughout their shifts. These modular frames hold all sorts of things like tools, those special mats that help prevent foot pain after long hours standing, and those arms that keep cables organized instead of tangled up everywhere. According to some research from last year, workers in car factories saw about an 18% boost in productivity when using these adjustable setups. Another plus? Aluminum conducts electricity well enough to ground sensitive electronic parts during manufacturing processes without any issues. Plus, since most modern systems don't require bolts for assembly, companies can just swap out workstation configurations as needed when production lines change, which means good ergonomics doesn't get left behind as operations grow or shift.

Integration of Linear Motion and Control Systems Using Aluminum Profiles

Support Structures for Linear Motion Systems and Automation Components

Aluminum profiles serve as precisely engineered bases for all sorts of linear motion parts like ball screws and servo motors. The tight dimensional control these profiles offer, typically around plus or minus 0.1 mm, means everything lines up correctly when it comes to those linear guides and bearings. This kind of precision really matters in fast paced operations such as packaging machines and CNC equipment where even small misalignments can cause big problems over time. More and more factories are turning to T-slot extrusions for their frame building needs lately. These modular systems make it possible to slot in stepper motors, various sensors, and even lubrication systems right into the heart of automated production lines, creating flexible setups that adapt well to changing manufacturing demands.

Precision Alignment and Vibration Damping in Aluminum-Based Frames

When it comes to reducing harmonic resonance, anodized aluminum extrusions offer a significant advantage over steel frames, cutting down vibrations by around 40 to 60 percent according to MHI research from 2023. This makes them particularly valuable for those delicate semiconductor wafer handling robots where even minor disturbances can cause problems. The design of these extruded channels gives engineers room to incorporate rubber dampeners right within the structural parts themselves, helping maintain positional accuracy under 5 micrometers even when running nonstop. And let's not forget about thermal stability either. With a rating of plus or minus 0.03 mm per meter per degree Celsius, this material stands up well against warping issues in areas where temperatures might swing by as much as 30 degrees Celsius throughout the day.

Case Study: High-Speed Packaging Line Utilizing Aluminum Guide Rails

When a chocolate bar producer swapped out their old steel guide rails for aluminum extrusions, they saw production speeds jump from 450 to 550 units per minute, a 23% improvement overall. The lighter aluminum components cut down on system inertia by around 18 kg per square meter, which meant they could downgrade to smaller servo motors while still maintaining performance. This switch saved them about 14% on energy costs too. Another benefit came from those custom made aluminum clamps that let workers adjust product lanes much faster when switching between different SKUs. For anyone running a high volume confectionery operation, these kinds of improvements make all the difference in staying competitive without breaking the bank on maintenance and power bills.

Integrated Control System Frameworks Using T-Slot Aluminum Profiles

T-slot profiles facilitate centralized mounting of PLCs, HMIs, and power supplies within robotic workcells. Industry analysis shows 87% of automotive tier-1 suppliers now integrate control cabinets directly into aluminum framing systems, cutting installation time from 8 hours to just 90 minutes per station.

Cable Management and Panel Mounting in Automated Manufacturing Systems

Using extruded cable channels made from aluminum can cut down on wiring work by around 35% when compared to old school tray systems. What makes these channels really useful is the built-in DIN rail slots that let electricians mount circuit breakers and terminal blocks right where they need them. Plus there are those handy T-track systems which make it possible to adjust touchscreen panels without needing any tools at all. One manufacturer actually saw their changeover times drop dramatically after implementing these solutions. Instead of spending nearly an hour switching between different product runs, they now manage the whole process in less than seven minutes flat.

FAQ

What are the advantages of using T-slot aluminum profiles in automation systems?

T-slot aluminum profiles offer modularity and reduced weight compared to steel, allowing for quick assembly, reconfiguration, and reduced setup times. They eliminate the need for welding, which reduces labor costs and time.

Why choose aluminum over steel for building robotics and automation structures?

Aluminum provides a better strength-to-weight ratio, superior corrosion resistance, and allows faster reconfiguration times. It's especially beneficial in applications where modularity, precision, and vibration damping are critical.

How does the use of aluminum profiles impact the production costs and efficiency?

The use of aluminum profiles can significantly reduce production costs by cutting reconfiguration times, energy consumption, and maintenance costs. They also enhance production efficiency due to faster setup and adaptability.

Table of Contents

-

Modular Frameworks for Automation Systems Using Aluminum Profiles

- The Role of T-Slot Aluminum Extrusions in Automation Frames

- Modular Design for Robotic Cells Using Aluminum Profiles

- Reconfigurable Automation Setups with Lightweight Framing

- Case Study: Deploying Aluminum-Based Cells in Automotive Assembly Lines

- Trend: Shift Toward Flexible Manufacturing Systems Using Aluminum Extrusions

- Robotic and AMR Structures Built with Aluminum Profiles

- Conveyor and Material Handling Systems with Aluminum Extrusions

- Machine Guarding, Workstations, and Safety Compliance with Aluminum Framing

-

Integration of Linear Motion and Control Systems Using Aluminum Profiles

- Support Structures for Linear Motion Systems and Automation Components

- Precision Alignment and Vibration Damping in Aluminum-Based Frames

- Case Study: High-Speed Packaging Line Utilizing Aluminum Guide Rails

- Integrated Control System Frameworks Using T-Slot Aluminum Profiles

- Cable Management and Panel Mounting in Automated Manufacturing Systems

- FAQ