One of the most abundant metals on earth

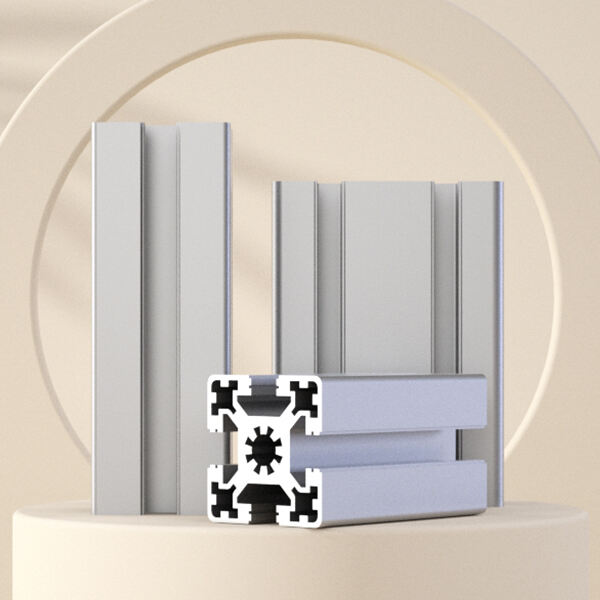

Aluminum is used very frequently in many everyday products as well because it is strong and light. Order aluminum extrusion and maintain dimensional stability understanding why we order aluminum extrusion to keep the dimensions dominant crossfire what you need to know about antennas when manufacturing aluminum products, such as Common’s aluminum extrusion profile, it is important to maintain dimensional stability. Dimensional Stability refers to maintaining shape and size of the product to consistently provide its expected physical properties with respect to time. These factors can significantly affect the dimensional stability of aluminum extrusions and it is therefore important to understand and recognize these threats in order to avoid warp and distort.

First step to achieving high-quality aluminum extrusions

It is knowing about dimensional stability and the factors that impact it. Another component of the process is temperature. Because aluminum grows and shrinks with temperature, temperature control is essential when extruding aluminum. Cooling the extruded aluminum is done properly to avoid warping and distortion. The pressure level is a significant parameter in the process of extrusion, and it can also impact the dimensional stability. Aluminum is susceptible to deformation from high pressures, and therefore requires careful pressure control so that dimensionality stays consistent.

In storing aluminum extrusions, it is important to use the right storage techniques and practices so as not to cause warping and distortion. Aluminum is a soft metal and it can get easily bend or dented if not treated gently. The use of supports and protective packaging is important to avoid any twisting or bending during transportation or storage of aluminum extrusions. Keeping the aluminum profile extrusions in a cool and dry place can also prolong the cross-section of your tool. These types of precautions should be able to keep Common's aluminum extrusions in acceptable Repeatability Annex dimensions.

Choosing the appropriate alloy and heat treatment Attributes

To help support tolerance stability on high productivity Aluminum Extrusions in either long or short-run production. Alloys vary in their properties so it is important to select an alloy which is tailor made for the particular application of extrusion. Furthermore, heat treatment can influence the strength and stability of the aluminum, for this reason it is essential to avoid mistakes during the heat-treatment process to reach wanted dimensions. Complex must collaborate with their suppliers to identify the best alloy and heat treatment for their high-volume extrusions.

Tools Set Up: Die and Tooling Maintenance The shape of the dies direct the form, quality, and tolerances as communiqué between the client/finish software requirements. Wear of both dies and tools in the extrusion process can change dimensions of the extruded aluminum. Prevent check dimensions errors due to issues in die and tools by having the dies and tools inspected periodically, as well a maintenance. Common should have a maintenance schedule to maintain the dies and tools so they do not cause them to making repeated acceptable product.

Critical quality control measures

In addition to those essential design factors, there are critical quality control measures that are necessary to maintain the right dimensional accuracy of aliminium extrusions. Quality checks should be conducted at every step of the manufacturing process and dimensions are key areas that need to remain close to tolerance, failing which having a consensus with common should your only resort. One easy way to prevent this is by applying measurements at the different points of production using tools and a few inspection techniques. With extensive inspection and professional high-standard setting, we are able to ensure that all of our aluminum custom aluminum extrusion profile meet the required dimensions and specifications.

So, finally dimensional stability is very important for good quality aluminum extrusions. Common can maintain consistent product dimensions in their long-run aluminum extrusions by understanding the factors affecting dimensional stability, handling and storing properly, selecting proper alloy and heat treatment, keeping die and tooling up to scratch, whilst implementing a quality control strategy. By adhering to this, they can come up with best aluminum extrusion fit to the requirements and standards of their clients.