Aluminium extrusion is Revolutionizing. How modern factories construct things? It is a metal molded by pushing it through a mold to form strong, light parts. This process, helps create parts that fit precisely what factories need. At Common, we watch as this material helps factories run more smoothly and produce better products. Since extruded aluminium is easy to handle yet strong, today many factories use it for a variety of parts in their machines and buildings.

Why Wholesale Industrial Uses Extruded Aluminium may be the Best Option

When factories need many parts at one time, extruded aluminium often takes the lead. That makes it light but strong, so it holds up to hard use without breaking or bending readily. As wholesale buyers, we want materials that last long and don’t add too much weight; this is particularly important when building machines or storage racks. Aluminium fits these needs well. And the way it’s made lends itself to so many shapes and sizes. This way, factories can receive precisely the pieces they need without doing extra work. At common, we've had a customer request custom aluminum parts that would work perfectly with their specialty machines. Another factor that makes extruded aluminium to be used is its non-rusting nature similar to steel. That means objects made from it will remain strong even in wet or damp environments. Factories which use extruded aluminum will save on costs as they do not see the need to replace parts frequently or have to spend hours cleaning rust. Plus, aluminum is highly recyclable. That makes it a great option for companies looking to be eco-friendly. Prices are fair and the shipping is dependable when purchasing in bulk. Common works zealously to fulfill big orders so factories don’t run out of the parts they require. In other words, extruded aluminum brings strength, lightness and flexibility in one package that wholesales buyers can not overlook.

How Extruded Aluminium Profiles Make Modern Factory Production More Efficient

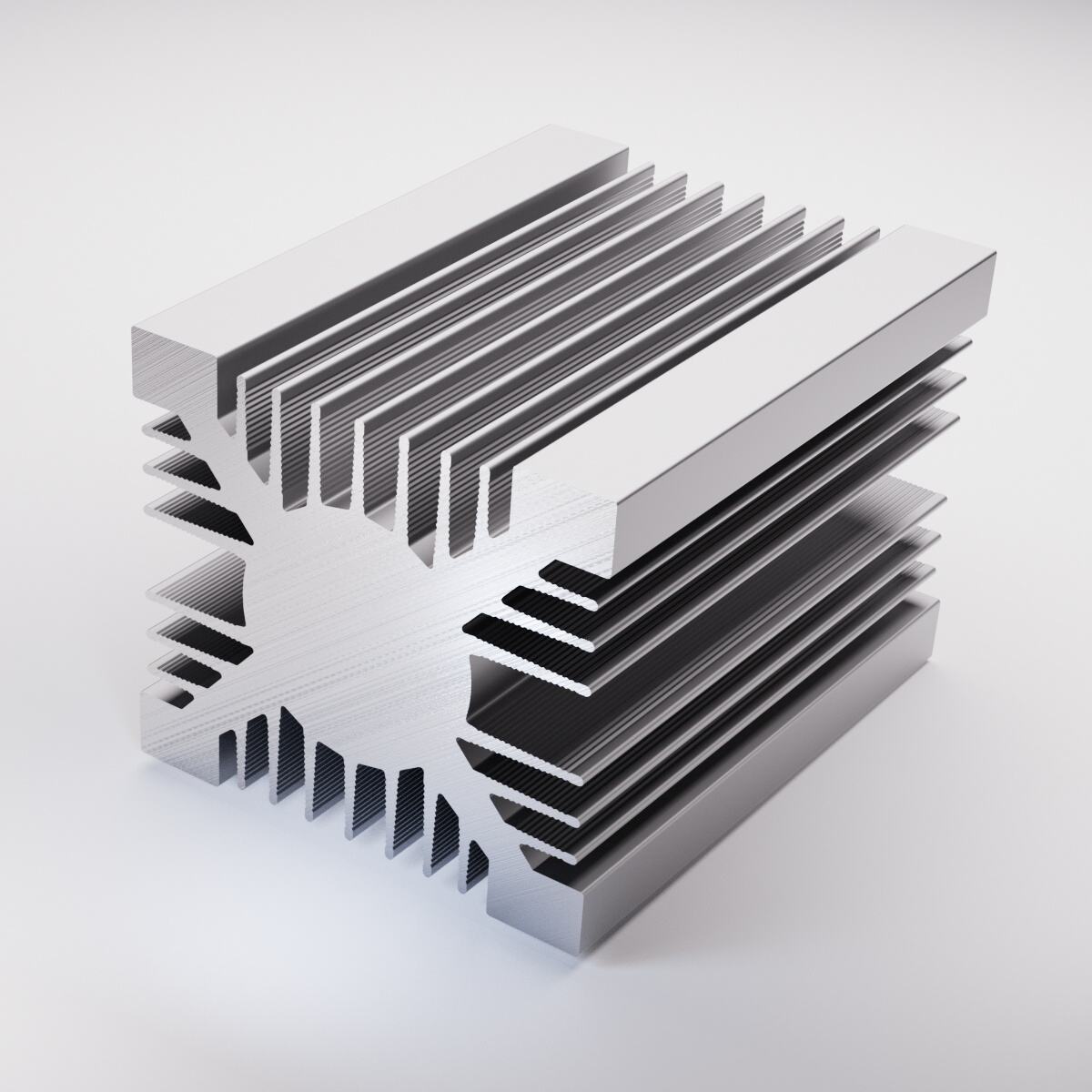

When you are considering different materials to use for your factory processes and products, probably the most important things you will need to pay attention to is their level of flexibility. Today’s factories want to make things faster and better. Which is where the extruded aluminium comes in on lots of levels. For starters, it is easy to cut and connect, which makes assembly a breeze. For example, frames of machines made from aluminium can easily be constructed and modified, if necessary. That means factories can address malfunctions or update machines without having to wait weeks. At Common, we’ve worked with factories to develop extruded-aluminum parts to make their machines run more smoothly and without as much downtime. A side benefit of aluminum’s light weight is efficiency: Machines need to use less energy. When components are lighter, motors and tools don’t need to labor as much. This can save money on electricity and spare wear and tear on machinery. The other thing is that extruded aluminum is a good heat mover. This is valuable in very hot machines where the help of aluminium components to keep things cool can make a difference. Cooler machines break less often and can run for longer periods of time. Factories that increase their speed and reduce costs remain competitive in the market. One way to achieve this objective is with extruded aluminum. It also allows factories to create flexible systems capable of quickly changing when orders or products change. Such flexibility is particularly valuable today, at a time when demand can change abruptly. Common’s track record demonstrates that aluminum extrusion factories typically face fewer delays and enjoy improved production. When workers have well-fitting parts and machines that run smoothly, the rest of the work is made easier. So extruded aluminium is not only a metal, it’s also just the kind of tool that helps factories work smarter and faster every day.

Common Problems of Extruded Aluminium and How to Overcome them

It has become increasingly popular thanks to its use in modern factories but, like any material there can be some common problems you will need to watch out for. One issue is just scratches or dents on the surface. As aluminium is a softer metal than steel, it can become dented in handling or shipping. To prevent it workers need to wear protective coverings and be cautious when working with the aluminium. Another problem is corrosion, particularly when aluminium is exposed to water or chemicals. While aluminium does form a naturally occurring, protective thin lay of oxide to cover the metal surface, this layer can wear off or be damaged. To prevent corrosion, factories can put special coatings or paints on top of the metal to block moisture and harmful substances from contacting the metal. On occasion, you might have a part made from extruded aluminium be out of tolerance as the size is not identical throughout production. Obviously, this makes machines difficult to put together. In order to prevent this, it's crucial to have a controlled process of extrusion with careful measuring when cutting and shaping the aluminium. Finally, aluminum can sometimes bend or lose its flatness permanently if too much force is exerted upon it or high levels of heat are applied to it. Our factories must make their shapes delicate and be cautious of putting heavy loads on the aluminium parts. Thinner and more appropriate for each part also help them become better stronger. At Common, we work hard to ensure our extruded aluminium products are manufactured with these challenges in order. We collaborate with factory owners and engineers in order to supply aluminum parts that are both easy-to-use and durable. Learning these common issues and how to prevent them will allow the factory to make the most of extruded aluminium, all while keeping machinery operational.

What Are The Key Factors That Affect The Service Life Of Extruded Aluminum In Industrial Application

There are many crucial factors for the durability of customized aluminum profile in factories. First, how good or not the aluminium is to begin with is very important. Good-quality aluminium with fewer impurities should be stronger and last longer. At Common, we choose our materials with care to ensure that they are of the highest quality. Second, there is external physical shaping of the extruded component. When you get those parts to the right thickness, and they are shaped correctly, they can better withstand the stress or weight that is placed upon them. Hollow sections can, for instance, be strong but lighter than solid sections, letting the machines work effectively without picking up an excessive amount of weight. Thirdly, post-extrusion treatment of the aluminum makes a big difference. Heat treatments can strengthen aluminium, and protective coatings slow down rust and corrosion. In factories where chemicals or moisture are common, such coatings help protect the metal from damage. Another such factor is the medium where aluminium is employed. If the factory is in a salty or very humid location, it might be necessary to use additional protective covering from the aluminum. Secondly, the upkeep of the aluminum makes a difference with regard to its lifespan. Small problems can be caught before they turn into larger ones through regular cleaning and inspection. grease, and other harmful chemicals accumulate Some people have noted that won't frag after cleaning 502 ablation cleaner is a chemical Guys Products It? Finally, how aluminium parts are connected or joined is relevant also. Cracks or breaks can be avoided by placing appropriate fasteners and not applying excessive stress on joints. Common knows about these factors very well and Common offers solution that keep extruded aluminium strong and trustworthy. We work with factories to select the correct products and maintain them appropriately, so they can keep their equipment both safe and in good working condition for many years.

Why Factory Owners are Relying on Extruded Aluminium for Structural Needs

An increasing number of manufacturers are opting for aluminum extruded profile when their industrial facilities need supporting. One major reason is that extruded aluminum is very light, but it’s still quite strong. This makes it easier to transport and install than heavier metals, such as steel. Lighter structures also impose less demand on building foundations and machines, which can save money in the long term. Another point is that extruded aluminum can take any form. Since it is produced by pushing molten aluminum through a die, it can assume complex shapes that suit particular needs. This allows factory owners to order custom parts that are an exact fit for their machines or buildings. The smooth finish of extruded aluminium also appears to be clean and professional, which are great functionality for the modern factory with a need to look organised. Aluminium also doesn’t rust and corrode, so it will have a longer life in fierce factory conditions too. This eliminates the necessity of repurchasing new parts and cuts down on time consumption as well. Factory owners also appreciate that extruded aluminium can be easily recycled. Recyclable materials also help organizations be environmentally responsible and meet sustainability targets for green Manufacturers. Here at Common, more and more factory owners are now opting for our extruded aluminium products as these represent an excellent combination of strength with versatility or flexibility and longevity. Our products assist the factory in constructing sturdy frames, supports and machinery that perform well and look good. This rising trend is further evidence that extruded aluminium forming a major aspect of contemporary factory design. It allows factories to work smarter, safer & more efficiently - that's why so many individuals count on Common for their aluminum.

Table of Contents

- Why Wholesale Industrial Uses Extruded Aluminium may be the Best Option

- How Extruded Aluminium Profiles Make Modern Factory Production More Efficient

- Common Problems of Extruded Aluminium and How to Overcome them

- What Are The Key Factors That Affect The Service Life Of Extruded Aluminum In Industrial Application

- Why Factory Owners are Relying on Extruded Aluminium for Structural Needs