×

×

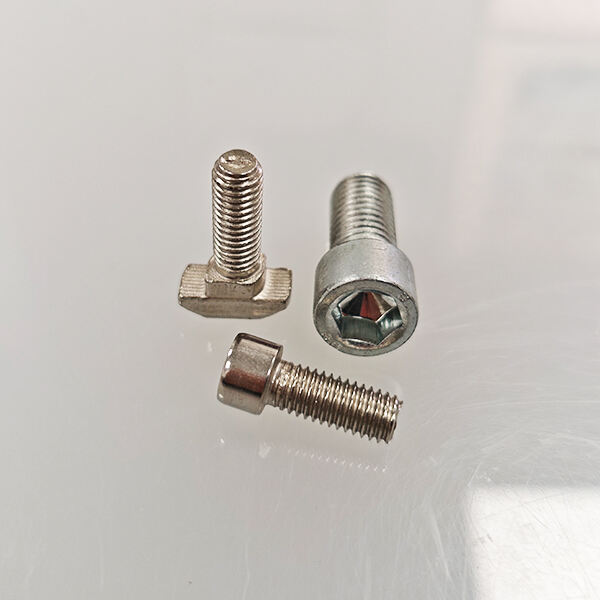

The Allen hex bolt is a specific type of fastener that is a tool used to hold materials together well. Its shaft is long and round, but has a flat end. The flat end is so it fits snugly in a little shape at the top of the what is called a bolt, specifically a hexagonal. Alternatively, it’s called a drive socket (hexagonal shape). The bolt is turned and tightened with some sort of special tool called an Allen wrench. That's called an L wrench and it's helpful because it provides a great angle to grip the bolt.

There are a lot of benefits of using Allen hex bolts in your projects! The best thing about these bolts is that they are very easy to use. But even if you are a beginner and don’t have much experience, you can get the job done with them. They are also incredibly strong and can last for years, so they are able to hold materials together really well without getting any loose.

The other great thing about Allen hex bolts is that they also come in a multitude of sizes and materials. This, in turn, makes them useful for all sorts of tasks. For example, they may be made of materials such as stainless steel, which is exceptionally strong and does not rust easily, or titanium, which is even stronger but lighter. There are brass bolts, which are pretty but don’t corrode. Being composed of various materials, you can select the appropriate one on your project, based on whatever you want.

Important Factors To Consider When Choosing The Correct Size Allen Hex Bolt For Your Application First, think about how thick are the materials you want to connect together. This will allow you to determine how long of a bolt you need. A bolt should be long enough to pass through both materials you are combining fully, and you will also want a bit more length so you can get a good hold on the nut.

Now, let’s look at how to tighten Allen hex bolts securely and effectively. You start out by inserting a bolt through the materials you wish to fasten together, and then screw on the nut at the end. Then, take your Allen wrench and turn the bolt to the right, otherwise known as turning it clockwise. This will allow tightening of the nut and ensures better locking of the materials.

You have to be careful and not overtighten the bolt, because that's really important.” Don't tighten it too much, which can fracture the materials, or even damage the bolt itself. Instead, you would tighten it until it felt snug and secure, and then turn it just a little more — a quarter turn or so — to ensure everything was tight and safe.

Making the right decision about when to go for good quality Allen hex bolts is crucial, notably for strength and reliability applications. First, quality bolts are more functioning and less likely to fail when you need them most. This will ensure that you are safe as well as the tools and equipment to prevent them from getting ruined.