×

×

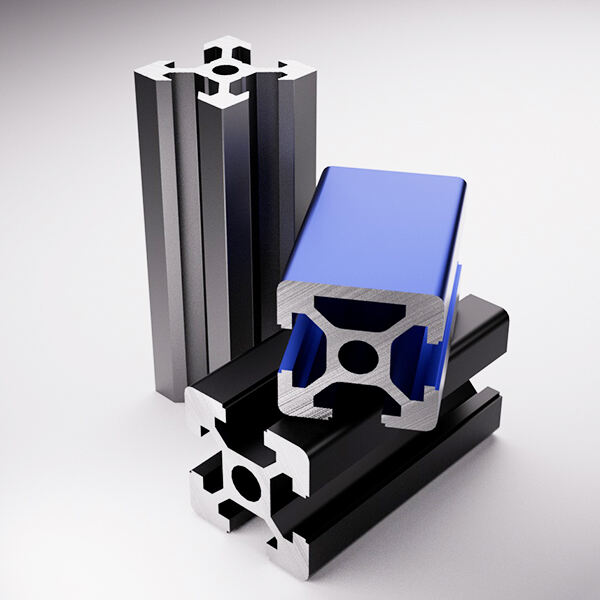

Aluminum extrusion is a unique process of forming shapes with aluminum. This technique functions by forcing the aluminum metal through a tool known as a die. The die itself is the shape that we want to create and as the aluminum goes through, it takes on the shape. This process was improved a lot in 2020. We hoped you would join us as we really excited at a company called Common to share all the good things about using Aluminum Profiles in your next build.

There are many advantages of using 2020 aluminum extrusion in your project. The biggest pros are that the material is very lightweight, durable, and non-corrosive. So when you build something, you can use a material that will be strong enough to stand up to bad weather, such as rain or snow, but still light enough for you to carry around easily. When you are working on large projects or have to move components from one location to another, this is particularly useful.

2020, a great choice for factory building. Factories are now able to create a countless number of similar parts without high investment simply by utilizing this material. The extrusion process is highly mechanical; in fact, machines do all the work. This enables factories to create all kinds of shapes and pieces quickly, speeding up the process and improving efficiency. This is great news for businesses because they can satisfy customer needs quickly.

aluminum extruded profile is one of the most versatile materials available for just about any building or engineering project. It is cut to custom shapes and formed on your specifications. It is also relatively straightforward to cut and assemble the aluminum, which further suits builders and engineers. It can also be painted or treated to be more resistant to the elements. Doing this not only helps to keep it safe from the weather but it also makes it look nicer and more appealing.

Aluminum is great for being eco-friendly, and it has a key role due to aluminum extrusion. You may ask, what about the sustainable aspect of it, and the answer is, the extrusion process produces less waste which is beneficial for our planet. It also uses recycled aluminum, meaning old aluminum materials can be made into new products. Factory waste contributes to global pollution, but when factories make parts using aluminum extrusion, they create a helpful reduction of their environmental impact. At Common, we truly value sustainability, so we understand how important 2020 aluminum extrusion is for our mission.

In 2020 and beyond, innovations for aluminum extrusion are on the horizon. Many technologies have emerged that enable even more freedom when designing and creating. Some of the most interesting developments, in particular, are the use of robots in the production process. That means that with the help of machines, some elements of the extrusion process can be automated and this will lead to consistency and efficiency in the extrusion process. This is crucial because it ensures every part produced is as good as the previous.

At Common, we strive to optimize our processes and materials. We believe in creating products that are not just effective, but also earth-friendly. First, we know that 2020 aluminum extrusion is a vital addition to the swing into our buildings and we look forward to finding more innovative methods and technologies that will allow us to continue to grow.